Repair or Replace a Rubber Lining?

Keeping your equipment safe is of the utmost importance whether you have storage tanks at a steel mill or you are piping slurries.

Rubber linings create a protective layer within your facility’s vessels and proper maintenance keeps your equipment running longer. Blair Rubber Co. has suggestions for storing and maintaining your rubber linings. However, when you do discover a hole, blister or other defect during an inspection, you have to decide on your next step.

Questions to Ask

Rubber linings protect your equipment from corrosion. But when signs of wear occur, it’s time to determine whether the situation needs a repair or replacement.

Here is a list of questions to answer to help guide your decision:

By answering these questions, you’ll get the perspective you’ll need as you weigh the impact on production and potential costs.

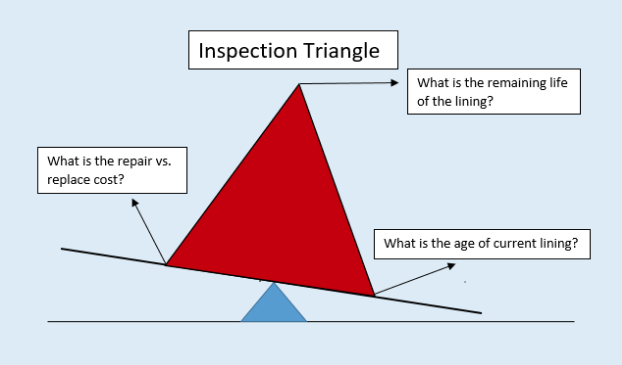

The Inspection Triangle

After you have assessed the situation, you can determine what your next step will be. Each rubber lining situation is different, especially in regards to the commodity. Your decision may differ if you are storing a highly-concentrated solution of HCL. It is a balancing act.

The three major factors in evaluating your potential solutions are:

- Remaining life of your lining

- Repair and/or replace cost

- Age of the current lining

For instance, if your lining has an expected 10-year life and a hole occurs after nine years, replacing the lining likely makes the most sense. However, if your lining has a hole after only three years, you may want to perform a repair.

Note, when determining the cost of repair, it is important to consider all factors. Know what caused the problem. If a chemical solution is under the lining, it may cause future problems. Even a 2” diameter blister can cause damage when liquid is trapped inside. Once a chemical is caught between the lining and the tank, cutting out the blistered area may not be an effective solution.

Common Rubber Lining Repair Scenarios

While every situation needs to be assessed individually, there are some general guidelines that applicators and end users can follow.

- If a large area of the tank is damaged and it is deeper than two plies, the lining needs to be replaced.

- Note, action is dependent on previous type of patch utilized.

- Light surface cracking 1/8 of lining thickness: no action needed.

- Medium surface cracking ¼ of lining thickness: buff and overlay.

- Severe surface cracking ½ of lining thickness: a replacement is necessary.

- Blisters less than 2” diameter: test to determine whether there is solution behind the lining. If it is solvent, it may be best to leave and monitor.

- Blisters more than 2” diameter: cut out, fill and overlay.

Remember, these are general guidelines to follow. Each situation calls for a closer examination. It is always important to consider the age of the lining when deciding whether to repair or replace it.

If you need help evaluating a rubber lining defect, contact our experienced team for guidance.